Home / News / Industrial Trend / [Laser Special Issue]Future applications of SMD LD

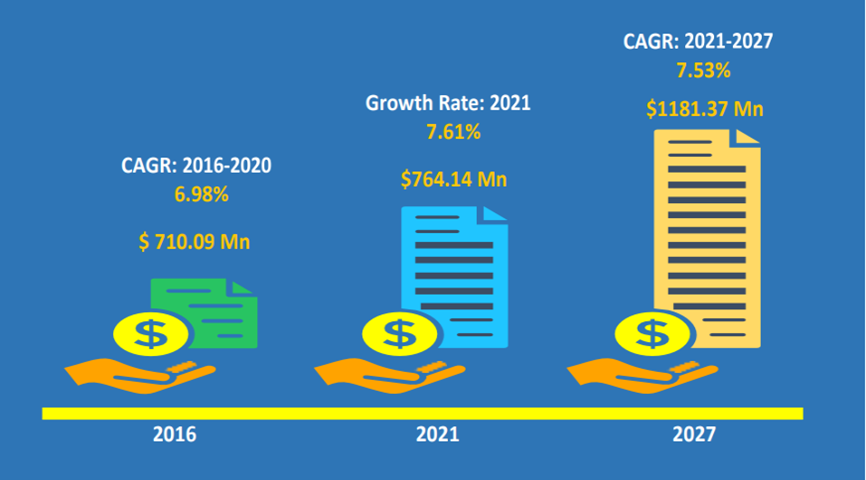

After more than half a century of development, laser has become inseparable from modern life, such as well-known medical beauty, optical storage, optical communication, facial recognition and semiconductor precision processing. Nobel Prize-winning technology has generated an annual output value of tens of billions of dollars. According to a QYResearch survey report, the global laser module market is worth US$710.09 million in 2020 and will reach US$1,181.37 million. The rise of the metaverse trend drives the vigorous development of the optoelectronics industry. It is estimated that by the end of 2027, the compound annual growth rate from 2021 to 2027 will be 7.53%, and the laser industry is optimistic for a long time.

Global laser module market size is expected to increase year by year (million USD) Expert Interviews and QYResearch, 2021

Semiconductor laser is the most widely used laser technology and belongs to the III-V group of semiconductor devices. At present, the application of laser in global medicine has achieved staged progress, which is divided into two categories: laser diagnosis and laser treatment (including laser beauty). The former uses the laser as the information carrier, and the latter uses the laser as the energy carrier.

Because lasers are superior to traditional treatment methods in terms of accuracy, efficacy and safety, various laser medical equipment has entered a variety of surgical, skin, ENT, oral, cardiovascular and oncology departments. It can perform surgery or interventional treatment by coagulating, cutting, and vaporizing the diseased tissue to achieve clinical therapeutic effects.

Laser application in CT/MRI, oral care and fat reduction beauty

The energy system requirements of electronic products, industrial equipment and electric vehicles are developing in the direction of small size and high power, so the size of power components must also be reduced to meet future product development trends. Mr. Neil Tung, general manager of LECC Technology, believes that the goal of power component suppliers is to try to provide the power density of components in a smaller package.

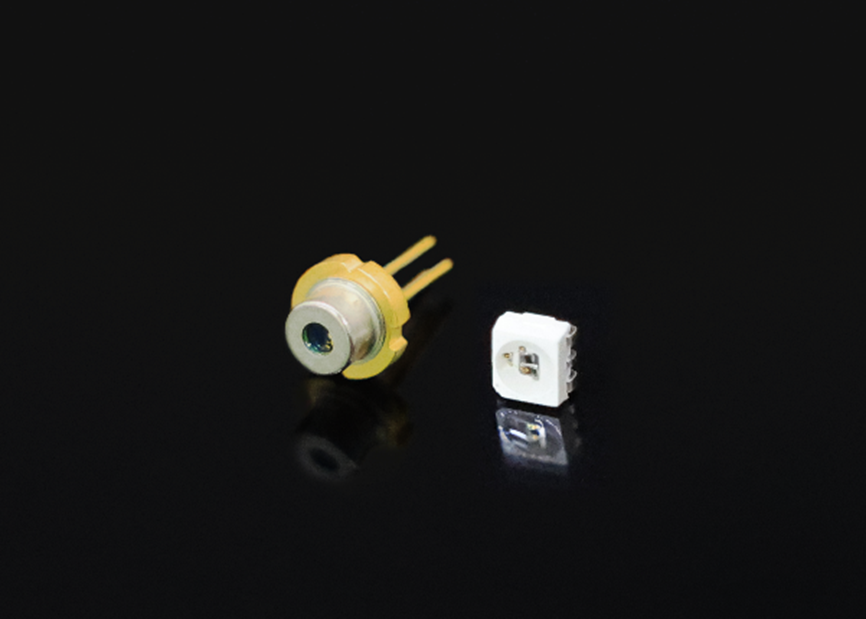

Most of the laser packaging technologies currently used in the healthcare field use TO packaging. The TO package is designed with a large number of pieces. During production, it is necessary to process complicated processes such as cutting feet, artificial inserts, and soldering one by one. Taking LECC's SMD packaging technology as an example, there are three series of products: SMD Laser Diode, SMD Laser Module and SMD VCSEL. The size of the currently developed SMD LD is only 3.4x3.3mm, and its weight is 0.3g compared to TO-56 package. It is reduced to 0.027g, which is about 91% lower in weight, and the height is reduced to 0.8mm compared to the TO-56 package of 3.5mm, which is about 77% lower in height. It is lighter and shorter in product application and has a service life of up to 11,000 hours. The biggest advantage of the small divergence angle and energy concentration is that it can reduce the volume of the product, make the product easy to cooperate with automated production, and save production losses and man-hours.

At the same time, the built-in Zener diode has better anti-static ability, reliable operation and high efficiency, and is also very suitable for consumer healthcare applications such as low-energy laser therapy. The various advantages of SMD packaged laser diodes are more in line with the mainstream direction of industry research and development. The small size can increase the flexibility of customer design products and reserve more space for system upgrades of customer products.

The thickness difference between TO package and SMD package

SMD LD is small in size, low in cost and widely used in a variety of applications. LECC integrates the three major fields of optics, structure and electronics. Under the integrated management strategy of R&D, proofing and production, it also provides SMD or TO packaging. emitter diode solution. LECC can customize specific wavelength, optical power, light spot shape and divergence angle according to needs.

LECC aims at the healthcare business opportunities of wearable devices after the epidemic, and is expected to increase the penetration rate of lasers in healthcare applications in the future. In addition to its own profound technology in manufacturing laser modules, it is currently actively developing a series of product lines combining lasers with traditional Chinese medicine acupuncture, including photon energy laser belts, laser hair growth caps/combs, nose/ears laser care devices, etc. The goal is to enable new trends in home healthcare. The principle of laser acupuncture is to use low-energy lasers to irradiate acupuncture points or myofascial pain points. Lasers with fixed energy and frequency can promote the synthesis of granules and glands, increase energy sources, activate endocrine regulation, and achieve anti-inflammatory and recovery. Blood circulation effect. Compared with traditional acupuncture, people who are afraid of pain and needles can also choose painless and non-invasive laser acupuncture.

At present, the combined application of optoelectronic industry and medical industry has received strong support from the government. It is expected to become the next growth driver of Taiwan's industry, and also let the world see the true strength of Taiwan's optoelectronic industry. LECC Technology will also be in this field. Continue to develop new products, hoping to bring more people a healthy life with light healthcare.

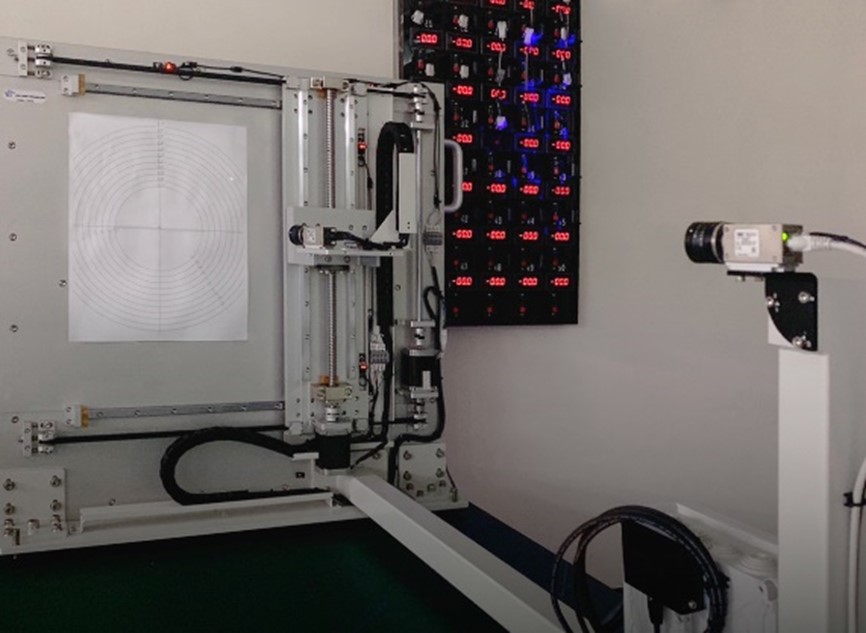

Since its establishment in 2000, LECC Technology Co., Ltd. LECC has been committed to the manufacture and sales of mid-to-high-end laser diodes and laser modules. Provide a wide range of wavelengths (405nm~980nm), from infrared to red, green or blue, we attach importance to the imagination of laser technology in every industry, not afraid of development challenges, lead customers to create innovative laser applications together, and continuously expand production capacity and improve the manufacturing process, and introduce laser module automation equipment to make the output and quality more stable.

The founder and R&D team of LECC have professional and diverse knowledge, and the company actively deploys nearly 100 patents worldwide. Focusing on the field of optoelectronics, our products have been favored by well-known brands for many years, such as: GE, PHILIPS, SIEMENS, FUJIFILM, BOSCH, BYD, Electrolux, ECOVACS, flex, etc. are currently partners of LECC Technology.

In recent years, LECC has stepped into the business model of its own brand from the OEM manufacturing industry, with customers as the core value, and looks forward to opening up new market areas in the application of biotechnology and healthcare. In addition to SMD laser diodes and laser modules, we also produce other related products, such as laser caps, laser combs, laser acupuncture, UVC LED Sterilizers, laser masks, laser ear and nose healthcare, we can customize according to your needs Specifications and requirements OEM or ODM, we promise to provide you with excellent and innovative laser solutions!

Automated production makes the quality consistent

(the picture shows the suction and release Lens and automatic focusing machine)

Copyright © 2023 All Rights Reserved by LECC