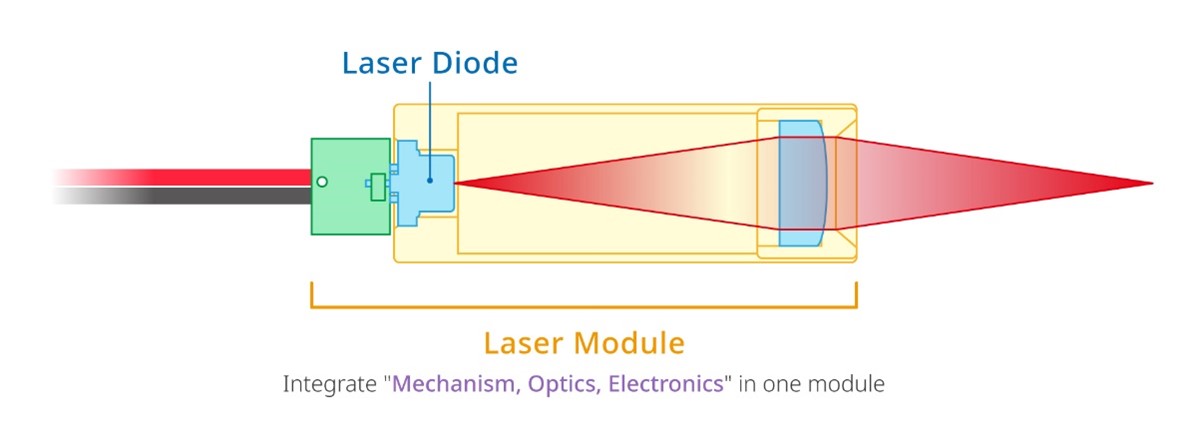

A laser module is a combination ofa laser diode(LD)、optical components、mechanical componentsandelectronic components.

⪧Optical components: Devices such as lenses, mirrors, or beam shapers that help control, focus, generate, and emit laser beams.

⪧Mechanism components: Hold LDs, optics and electronics in place.

⪧Electronic components: Drive the LD to produce a constant light energy output. In appearance, the laser module looks like a complete device, while the LD is more like a small electronic component.

Electronic components: Drive the LD to produce a constant light energy output. In appearance, the laser module looks like a complete device, while the LD is more like a small electronic component.

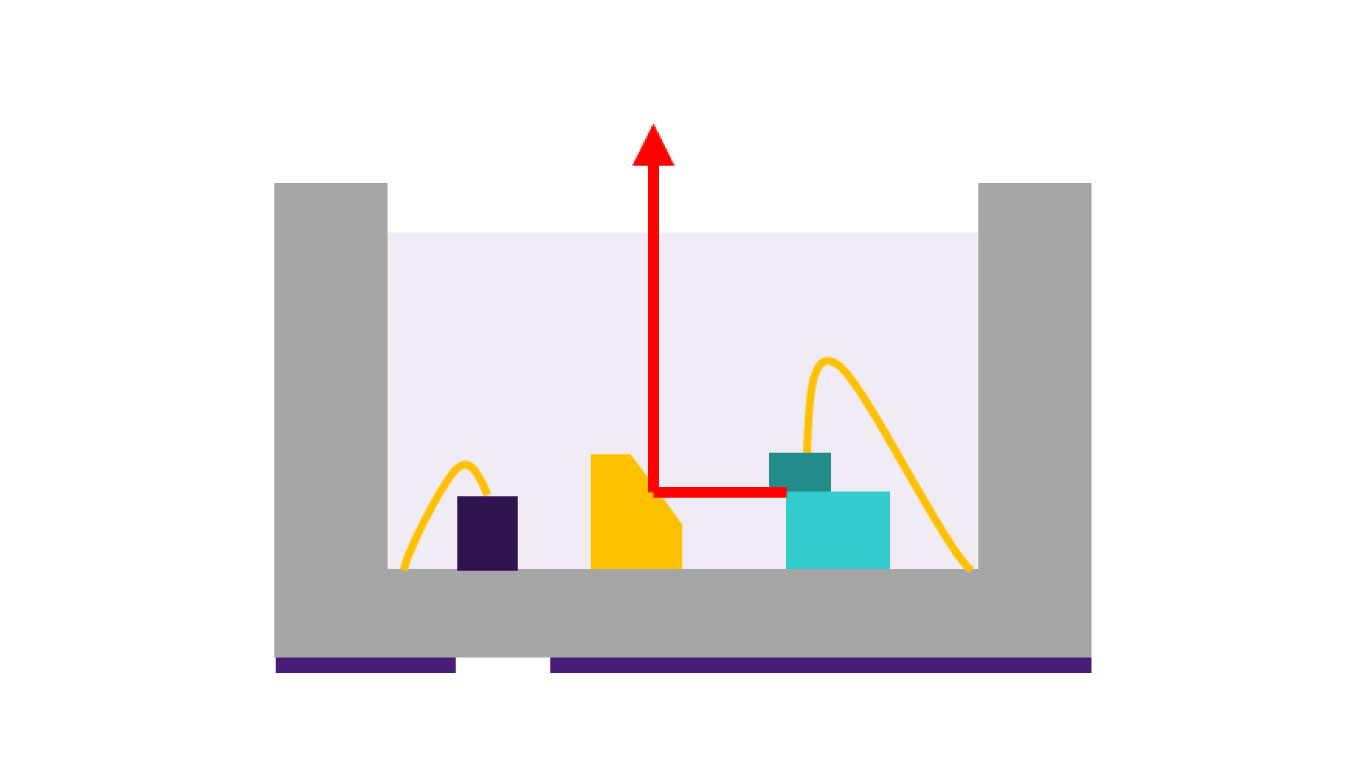

Part bonding technology continues to develop into smaller and lighter surface mount components (SMD), and special-shaped molds and semiconductor packages are becoming more and more diverse. Now it is the most important packaging method in modern electronic manufacturing industry. SMD is thin and light in size and consumes low cost and man-hours. The Zener Diode plays an important role in protecting LD in SMD.

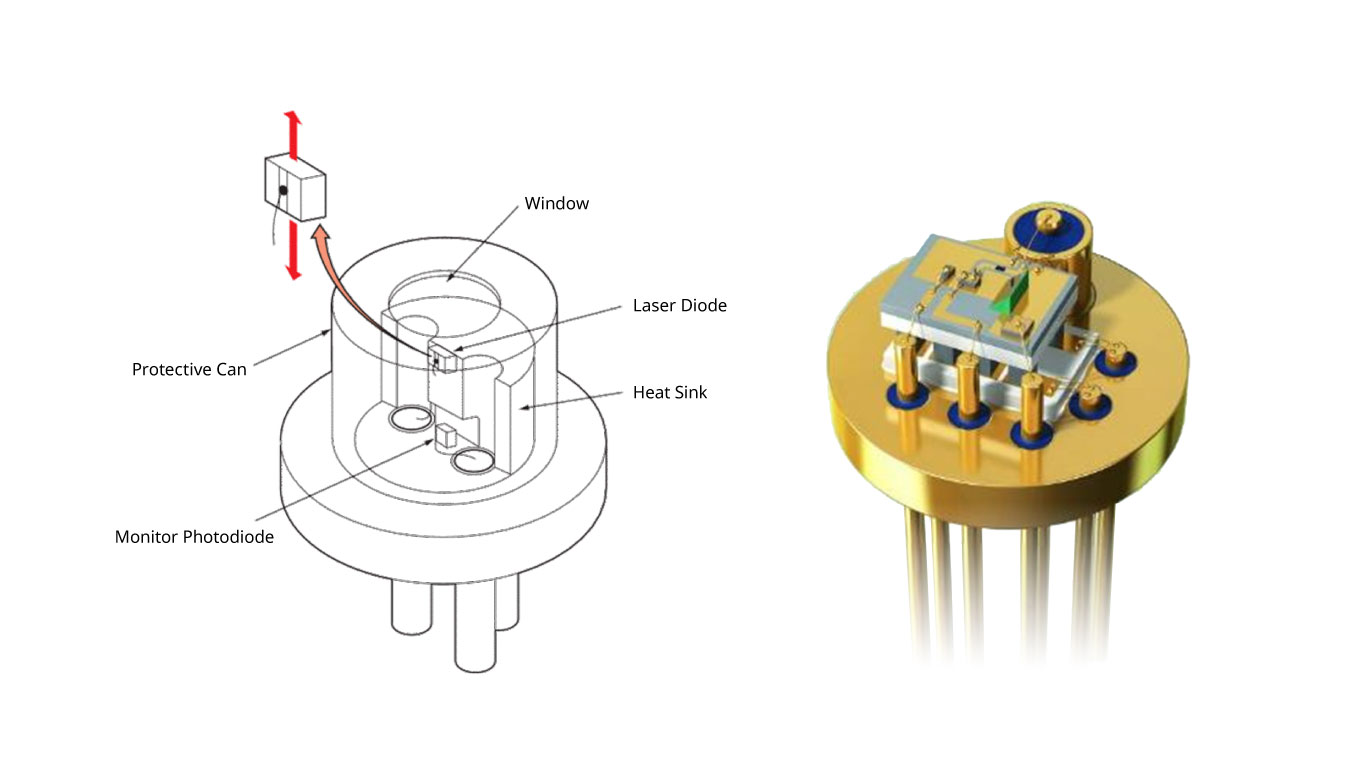

The transistor package (TO package) is composed of a metal shell and pins. Metal helps to dissipate heat. Its characteristics and dimensions vary according to different manufacturers and models, so the device type and performance requirements need to be considered when selecting. TO packaging is very practical in high power and high temperature applications because of its good heat dissipation performance and metal protection.

| TO package | SMD package | |

| TO-33/35/38/46/56 TO-5/c-mount |

Packaging method | 2835/3434/5050…etc. |

| Traditional laser module | laser module | Miniaturized laser module |

| Single/double wave | Available wavelengths | Single/Double/Multiple waves👑 |

| Larger | volume | smaller👑 |

| Cylindrical or other | Appearance | rectangular or square |

| More space and manpower consuming | cost | Reduces cost and space👑 |

| Artificial through hole/wave soldering | Use technology | surface mount |

| easy👑 | Repair and replacement | complex |

| better👑 | Thermal performance | Poor |

| higher👑 | Inductor/Capacitor | lower |

| High Temperature, High Power Applications | Applicable to | Small/Lightweight, Low Power Applications |

|

|

TO packaging and SMD packaging each have their own advantages. The choice depends on individual application requirements, space and cost factors. If you are interested in our products, please feel free to write to us to discuss your needs. We will work hard to find the best solution for you.

Copyright © 2023 All Rights Reserved by LECC